Evaporation Capacity: 0.3-5.6t/h

Moisture content after drying: 12-15%

The rotary dryer adopts low-speed rotation, bending plate hammering to disperse the material; according to the different characteristics of the material, different types of lifting plates and anti-sticking measures are adopted, so that the high-temperature airflow is mixed with the material, achieving a uniform drying effect. The biomass rotary dryer is mainly composed of a barrel device, front and rear supporting roller devices, feeding and discharging devices, transmission devices, gear covers and other components. Mainly used for the drying various biomass materials, suitable for dye plants, fertilizer plants, chemical plants, pharmaceutical plants and other manufacturers.

| Model | Power(kw) | Evaporation Capacity(t/h) | Inner Temperature | Outlet Temperature |

| YGHGφ1.2*12*1 | 5.5+15+2.2+1.5 | 0.3-0.6 | 300-500℃ | 90-100℃ |

| YGHGφ1.5*12*1 | 11+18.5+3+2.2 | 0.47-0.91 | ||

| YGHGφ1.5*18*1 | 11+30+3+2.2 | 0.7-1.34 | ||

| YGHGφ1.8*18*1 | 18.5+37+3+2.2 | 1-1.9 | ||

| YGHGφ1.8*24*1 | 18.5+55+3+2.2 | 1.35-2.44 | ||

| YGHGφ2.0*18*1 | 18.5+55+5.5+2.2 | 1.25-2.3 | ||

| YGHGφ2.0*24*1 | 18.5+75+5.5+2.2 | 1.67-2.9 | ||

| YGHGφ2.2*18*1 | 22+55+5.5+2.2 | 1.51-2.68 | ||

| YGHGφ2.2*24*1 | 22+90+5.5+2.2 | 2.02-3.36 | ||

| YGHGφ2.5*18*1 | 22+90+3+3 | 1.96-3.32 | ||

| YGHGφ2.5*24*1 | 22+90+5.5+3 | 2.61-4.16 | ||

| YGHGφ2.8*18*1 | 22+90+5.5+3 | 2.45-4 | ||

| YGHGφ2.8*24*1 | 22+132+5.5+3 | 3.27-5 | ||

| YGHGφ3.0*18*1 | 30+110+5.5+3 | 2.82-4.39 | ||

| YGHGφ3.0*24*1 | 30+160+5.5+3 | 3.76-5.6 |

1. High thermal efficiency. high contact surface between the material and hot air.

2. Low maintenance cost

3. The design of the lifting plate in the cylinder is multi-angle,suitable for various materials.

4. Integral spiral rigid structure, won’t deform under long-term high temperature

5. Compliance with various dust and emission regulations

6. Intelligent PLC control system, saving labor

Rotary dryer applies for a variety of materials, such as wood chips, wood shavings, sawdust, straw, grass, alfalfa, rice husk, bagasse, efb fiber etc.

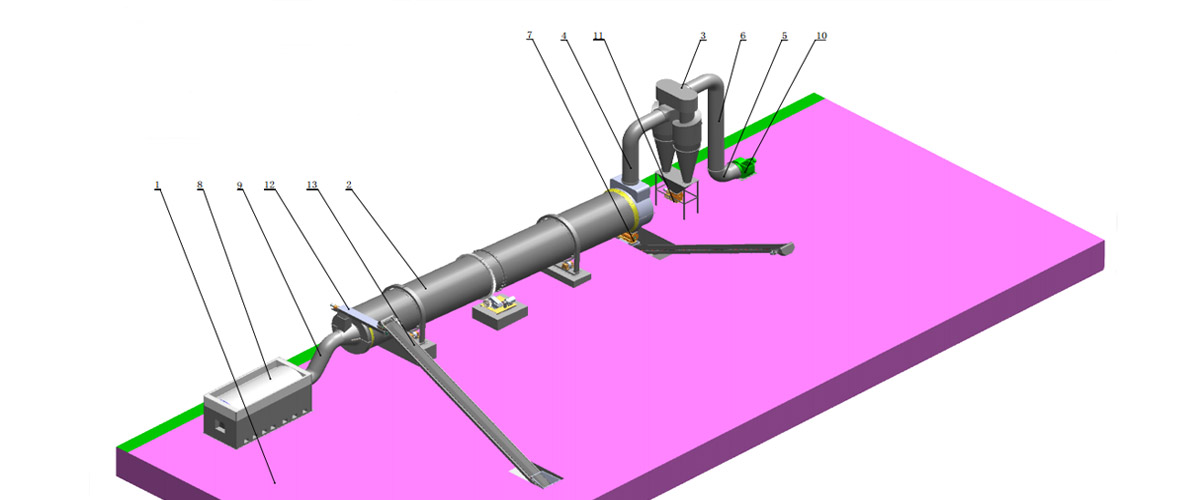

1. Rotary Dryer Base 2. Rotary Dryer 3. Cyclone 4. Pipe 5. Fan Blower Dialectal Switching 6. Pipe 7. Air Lock 8. Stove

9. Connecting Pipe between stove and dryer 10. Fan Blower 11. Air Lock 12. U-shaped Conveyor 13. Belt Conveyor

Q: ¿Es usted fabricante o empresa comercial?

Q: Soy nuevo en la industria de la biomasa, ¿cómo diseñar una planta de pellets adecuada?

Q: ¿Cómo prepararse para montar una línea de producción de pellets de madera?

Q: ¿Cómo se puede garantizar el servicio postventa?

Q: ¿Hay algunas máquinas en mi área que pueda observar?

Q: ¿Qué tipo de materias primas se pueden peletizar con la peletizadora RotexMaster?

Q: ¿Cómo confirmar la relación de compresión del molde para mi materia prima?

Q: ¿Cuál es el proceso principal para hacer pellets de biomasa?

Q: ¿Cuál es su flujo de trabajo si ordenamos equipos Rotexmaster?

Para todas las consultas, complete el siguiente formulario para enviarnos un breve mensaje y nos pondremos en contacto con usted lo antes posible.