Model: YMPJ216; YMPJ218; YMPJ2113

Capacity: 3-5t/h; 6-10t/h; 15-25t/h

Power: 55kw; 110kw; 315kw

Final Chips: 3-5cm

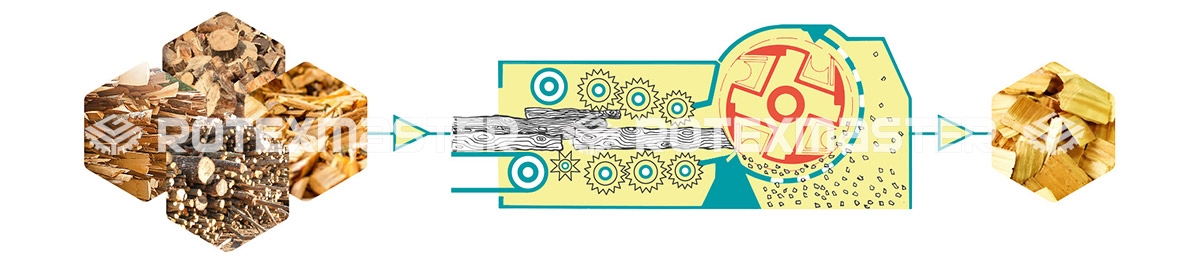

ROTEXMASTER has been manufacturing wood chipper machines for all kinds of application fields. Our drum wood chipper are known for their performance and quality, both nationally and worldwide. The wood chippers can chip wood logs, branches, timber, cross-cuts, slabs, furniture waste, bamboo, wood pallet into 3-5cm chips. The broad application ranges from sawmill disposal for the chipping of cross-cuts, slabs and chips to large chipping stations in wood-based material plants, power plant, paper plant– individually adapted to your application.

| Model | Power(kw) | Capacity(t/h) | Feeding Hopper Size(mm) | Chips Size(mm) | Weight (t) |

| YMPJ216 | 55+3+4+1.5 | 3-5 | 545*230 | 30 | 4.5 |

| YMPJ218 | 110+5.5+5.5+1.5 | 6-10 | 710*360 | 30 | 6 |

| YMPJ2113 | 220/315+11+11+3 | 15-25 | 1100*530 | 30 | 17 |

Drum wood chipper applies for various raw material, such as wood logs, branches, bamboo, timber, slab, various waste wood etc.

Factors such as the use of renewable energy such as biomass due to the consumption of traditional energy are driving the wood chip market.

In addition, the demand of the pulp industry is increasing, in which wood chips are used as raw material for pulp production, which also expands the wood chips market.

Furthermore, wood chips have been used for power plants and heat generation.

When burning, wood chips will generate biochar, also named charcoal. It can be either used as charcoal or returned to the soil as fertilizer. This will drive the wood chips market.

Feeding Hopper Size

What is the diameter of your raw material? This point is very important. As each wood chipper has certain maximum size.

Capacity

Different models of wood chipper are with different capacity, please let us know your capacity requirement, we can help you choose suitable model.

Blade Quality

The blade quality determines service life. Choose the material with anti-wearing.

Engine

We have electric and diesel engine type. If you use your wod chipper in the factory, you can choose electric type. If you want to use the wood chipper outside or in the forestry, diesel engine wood chipper is suitable for you.

General maintenance for wood chippers includes:

• Greasing moving parts at regular intervals

• Replacing the blades as necessary

• Replacing the screen as necessary

Astilladora de madera de tambor en Corea del Sur

Astilladora de madera de tambor en Corea del Sur

País: Corea del Sur

Capacidad: 15-25t/h

Materia prima: tronco de madera, madera de desecho

Astilladora de madera móvil en Japón

Astilladora de madera móvil en Japón

País: Japón

Capacidad: 8-10t/h

Materia prima: tronco de madera, madera de desecho

Astilladora de madera en Rusia

Astilladora de madera en Rusia

País: Rusia

Capacidad: 8-10t/h

Materia prima: tronco de madera, madera de desecho

Astilladora de madera en Tailandia

Astilladora de madera en Tailandia

País: Tailandia

Capacidad: 15-25t/h

Materia prima: tronco de madera, madera de desecho

Q: ¿Es usted fabricante o empresa comercial?

Q: Soy nuevo en la industria de la biomasa, ¿cómo diseñar una planta de pellets adecuada?

Q: ¿Cómo prepararse para montar una línea de producción de pellets de madera?

Q: ¿Cómo se puede garantizar el servicio postventa?

Q: ¿Hay algunas máquinas en mi área que pueda observar?

Q: ¿Qué tipo de materias primas se pueden peletizar con la peletizadora RotexMaster?

Q: ¿Cómo confirmar la relación de compresión del molde para mi materia prima?

Q: ¿Cuál es el proceso principal para hacer pellets de biomasa?

Q: ¿Cuál es su flujo de trabajo si ordenamos equipos Rotexmaster?

Para todas las consultas, complete el siguiente formulario para enviarnos un breve mensaje y nos pondremos en contacto con usted lo antes posible.