Model: YLQJ1.5; YLQJ2.5; YLQJ4; YLQJ6; YLQJ10

Capacity: 1-2t/h; 2-4t/h; 4-6t/h; 6-8t/h; 8-10t/h

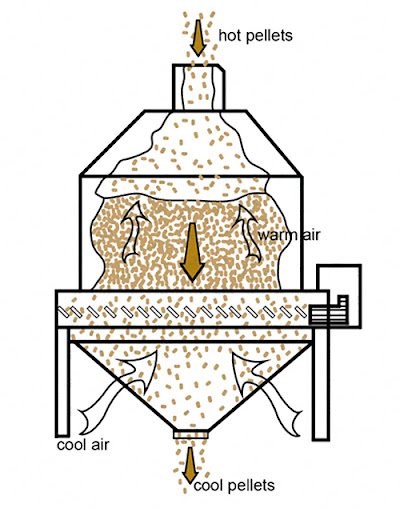

The counter flow cooler is a new type of cooler that is currently internationally advanced; Pellet cooler mainly cools high-temperature 60-80 ℃ biomass pellets, and the temperature after cooling is not higher than room temperature +3-5.

It adopts the counter-current principle to cool high-temperature and high-humidity materials. The natural wind enters the cooler from bottom to top, and the hot wood pellets enters the cooler from top to bottom. The natural wind passes through the material layer vertically and first contacts the material. The wood pellets are gradually cooled to avoid cracking on the surface of the pellets due to the sudden cooling. The air fully enters the cooler from the bottom, the entering area is large, so wood pellets can be fully and uniformly cooled.

Pellet cooler is generally used in conjunction with cyclone, fan, and air lock, which is used to absorb cold air and cleaning dust. A simple screener can also be installed at the bottom of the cooler to separate powdered dust and good pellets.

| Model | YLQJ1.5 | YLQJ2.5 | YLQJ4 | YLQJ6 | YLQJ10 |

| Power(kw) | 0.25+1.5+1.5+7.5 | 0.37+2.2+1.5+11 | 0.55+3+1.5+22 | 0.75+3+2.2+37 | 0.75+3+3+45 |

| Capacity(kg/h) | 1-2 | 2-4 | 4-6 | 6-8 | 8-10 |

1. Pellet cooler mainly cools high-temperature and high-humidity materials, after cooler, the temperature is not higher than room temperature +3-5.

2. Counter flow theory ensures that wood pellets can be cooled fully and uniformly. pellet broken rate is smaller than 0.2%.

Q: ¿Es usted fabricante o empresa comercial?

Q: Soy nuevo en la industria de la biomasa, ¿cómo diseñar una planta de pellets adecuada?

Q: ¿Cómo prepararse para montar una línea de producción de pellets de madera?

Q: ¿Cómo se puede garantizar el servicio postventa?

Q: ¿Hay algunas máquinas en mi área que pueda observar?

Q: ¿Qué tipo de materias primas se pueden peletizar con la peletizadora RotexMaster?

Q: ¿Cómo confirmar la relación de compresión del molde para mi materia prima?

Q: ¿Cuál es el proceso principal para hacer pellets de biomasa?

Q: ¿Cuál es su flujo de trabajo si ordenamos equipos Rotexmaster?

Para todas las consultas, complete el siguiente formulario para enviarnos un breve mensaje y nos pondremos en contacto con usted lo antes posible.